Cardiff company revolutionising sewage to energy conversion

Cardiff-based biotech company Genesis Biosciences has developed a novel, cost-effective and low site footprint solution to convert waste products into energy faster than currently possible while drastically reducing net energy consumption and final waste volumes.

Genesis’ Biogas Additive was developed at its South Wales laboratories by experts in the fields of microbiology and chemical engineering and is the latest product in the company’s range of innovative microbial solutions. The granulated powder enhances the performance of anaerobic digestion (AD) systems – which use bacteria to break down organic matter such as human waste, manure and food without oxygen – by increasing their biogas yields by as much as 100% and reducing the levels of undigested waste sludge disposed to landfill by half.*

Dr. Chris Charles, Senior Research Scientist and WWT Specialist at Genesis Biosciences, explains: “With a growing demand on companies and authorities to better their environmental credentials, decrease their waste and lower their CO2 emissions, AD and practices such as sludge-to-land are now being touted as circular economy champions.

“The ability to take human and other waste streams such as agricultural and food, and turn it into both energy and a fertiliser is attractive from a commercial aspect and a palatable ‘green’ concept that the general public can both understand and appreciate.

“Following the addition of the Evogen Biogas Additive to the waste material, the biogas conversion rate is accelerated, the volume of undigested sludge is reduced, and the biogas yield is significantly increased, resulting in lower running costs and a greater financial return. By partnering interacting Bacillus microorganisms with diverse extracellular enzyme profiles, we can ensure that our additive performs across a broad spectrum of organic substrates from sewerage sludge to agricultural and food wastes.”

Anaerobic digestion is fast becoming an integral part of the wastewater treatment process amongst local authorities and private companies. The ability to use microorganisms to produce methane rich biogas from sewage sludge and organic waste matter offers the potential to produce heat and electricity from an ever present and growing waste source.

To find out more about AD, or for more information about Genesis Biosciences and the range of waste water treatment solutions they offer, visit http://genesisbiosciences.co.uk/wastewater.

Case Study

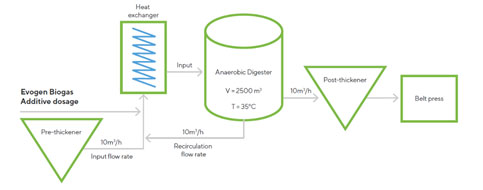

A single stage WWT sludge fed system was dosed with Evogen Biogas Additive over a 3-month period. The plant received 240m3 of WWT sludge per day with 10% of that volume coming from the chemical physical of landfill leachate. It operated at pH 7 and 35°C with a residence time of 10.4 days. A boiler was used to heat the sludge which was powered by both diesel and biogas. The sludge was disposed of via landfill after thickening using a flocculent and belt press.

Evogen Biogas Additive was dosed at 0.15% of the dry matter inlet concentration, with an initial slug dose of 50kg followed by a daily dosage of 10kg. Dosing was performed on site using a small modified tank to create a slurry with influent and which was then pumped into the system before the heat exchanger.

Fig.1. Layout of the single stage WWT sludge fed plant and the dosing tank set up to feed the system. A small footprint is required for the tank which mixed influent with product to create a slurry which was then dosed into the system

Results

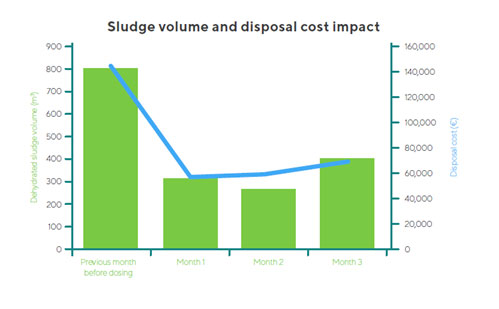

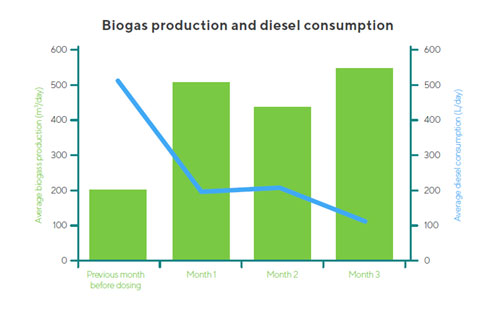

Dosing of Evogen Biogas Additive over the 3-month period was able to significantly reduce final sludge volume by half and double biogas production consistently during the trial period. This resulted in significant cost savings from less boiler diesel usage, lower flocculant use and lower sludge disposal costs. The overall cost saving over the trial period totalled just over €215,000.

The table below compares parameters before and after the dosing of Evogen Biogas Additive*.

Graphs show the relationship between sludge reduction and disposal cost over the trial period and biogas production and diesel consumption. It should be noted seasonal effects did not impact the results according to historical data.

Summary table of benefits.

*All figures approximate

Overall, Evogen Biogas Additive was used as a cost effective and simple to apply tool to not only improve plant efficiency but to also positively impact the environmental parameters of the plant by reducing sludge production and diesel consumption. Disposal fees and amounts associated with final sludge were greatly decreased whilst energy and heat generation from biogas were greatly improved, demonstrating the capability of Evogen Biogas Additive towards the benefit of a circular economy approach.

Evogen Biogas Additive is available now and supplied In Italy by Bierrechimica and Tillmanns Spa.