What are screw compressors and how are they useful?

What are screw compressors and how do they work? This is a question that many people have, but don’t know where to find the answer to. In this blog post, we will discuss what screw compressors are and how they work. Since compressors come in a variety of shapes and sizes, we will also cover some of the different types of screw compressors, as well as their cost and features. Finally, we will discuss in which industries screw compressors are commonly used. So, without further ado, let’s get started.

What Are Screw Compressors?

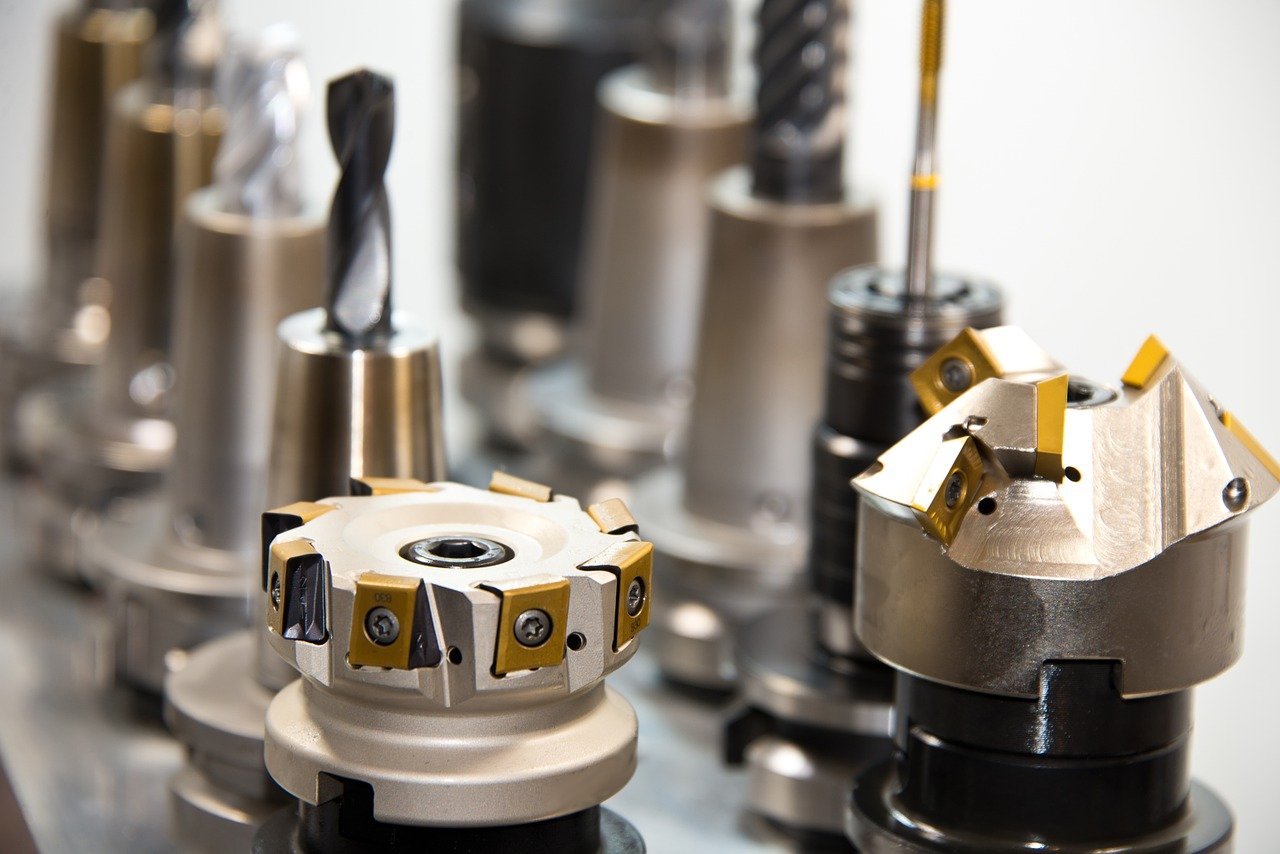

A screw compressor, also known as an air compressor, is a type of gas compressor that employs a rotary-type positive-displacement mechanism. These compressors are common in industrial applications, where larger volumes of compressed gas are required, for example, for large refrigeration cycles such as chillers, or for compressed air systems to operate air-driven tools such as jackhammers and impact wrenches. In addition, screw compressors are also used in oil and gas applications, where they are used to compress natural gas or petroleum products. A rotary screw compressor’s gas compression process is a continuous wide-ranging motion, so there is very little pulsation or surging of flow, as with piston compressors. This also allows screw compressors to be noticeably quieter and produce significantly less vibration than piston compressors, even at large sizes, resulting in some efficiency benefits.

How Do Screw Compressors Work?

Screw compressors work by using two intermeshing helical screws, known as rotors, to draw in air from the surrounding atmosphere. As the rotors turn, the volume between them decreases, resulting in the compression of the air. These rotors are driven by an electric motor, which can be either direct-drive or gear-driven. The compressor’s discharge valve then opens and the compressed air is discharged into a storage tank, where it is stored until it is needed. The amount of compression that a screw compressor can achieve is limited by the rotational speed of the screws and the size of the intermeshing gap between them. In addition, the temperature of the air being compressed also plays a role in limiting the amount of compression that can be achieved.

In What Industries Are They Used?

Screw compressors are used in a variety of industries, such as refrigeration, air conditioning, and oil and gas. In the refrigeration industry, screw compressors are used in a variety of applications, such as ice-making machines, refrigerator display cases, and walk-in coolers. Air conditioners also use screw compressors, which are responsible for compressing and circulating the refrigerant that cools the air in the home. In the oil and gas industry, screw compressors are used to compress natural gas or petroleum products. These compressors are also used in a variety of other industries, such as food and beverage, pharmaceuticals, automotive, and manufacturing. If you work in one of these industries, you can easily find screw compressors for your business, both online and in stores. Just keep in mind that you will need to purchase the right size compressor for your specific application.

Types of Screw Compressors

There are two main types of screw compressors: oil-free and oil-lubricated. Oil-free compressors are typically used in applications where the compressed air will come into contact with food or pharmaceuticals. For example, in the food industry, oil-free compressors are used to power vacuum packaging machines. Oil-lubricated compressors, on the other hand, are typically used in industrial applications where the compressed air will not come into contact with food or pharmaceuticals. For example, in the automotive industry, oil-lubricated compressors are used to power pneumatic tools, such as impact wrenches.

In terms of design, there are also two main types of screw compressors: single-stage and two-stage. Single-stage compressors only have one set of rotors, while two-stage compressors have two sets of rotors. This means that two-stage compressors can achieve a higher level of compression than single-stage compressors. Usually, two-stage compressors are used in high-pressure applications, such as oil and gas.

How Much Do They Cost?

Now that you know a little more about screw compressors, you might be wondering how much they cost. The price of a screw compressor depends on a variety of factors, such as the type of compressor, the size of the compressor, and the brand. For example, a small, single-stage oil-free compressor can cost as little as $500, while a large, two-stage oil-lubricated compressor can cost as much as $50,000. Besides these factors, the price can also be affected by the country in which you purchase the compressor. In general, compressors made in China are cheaper than those made in Europe or the United States. However, when buying a compressor, you should always focus on quality over price. After all, a compressor is a long-term investment, so you want to make sure you purchase one that will last.

What Are Some Features And Benefits Of Screw Compressors?

In addition to their affordable price, screw compressors also have a number of other features and benefits. For example, they are known for their reliability and low maintenance costs. In addition, screw compressors are also very efficient, meaning they use less energy than other types of compressors. Plus, because they have only a few moving parts, screw compressors are also much quieter than other types of compressors. If you’re looking for an affordable, reliable, and efficient compressor, a screw compressor is a great option. Furthermore, if you purchase a screw compressor from a reputable brand, you can be sure you’re getting a quality product.

As you can see, screw compressors are a versatile and affordable option for a variety of industries. Whether you need an oil-free or oil-lubricated compressor, a single-stage or two-stage design, you can easily find the perfect screw compressor for your needs. Plus, with so many different brands to choose from, you’re sure to find a compressor that fits your budget. So if you’re in the market for a new compressor, be sure to consider a screw compressor. You won’t be disappointed! Hopefully, this article was helpful to you!