Which Materials Can a Waterjet Cut | Guide to Waterjet Cutting

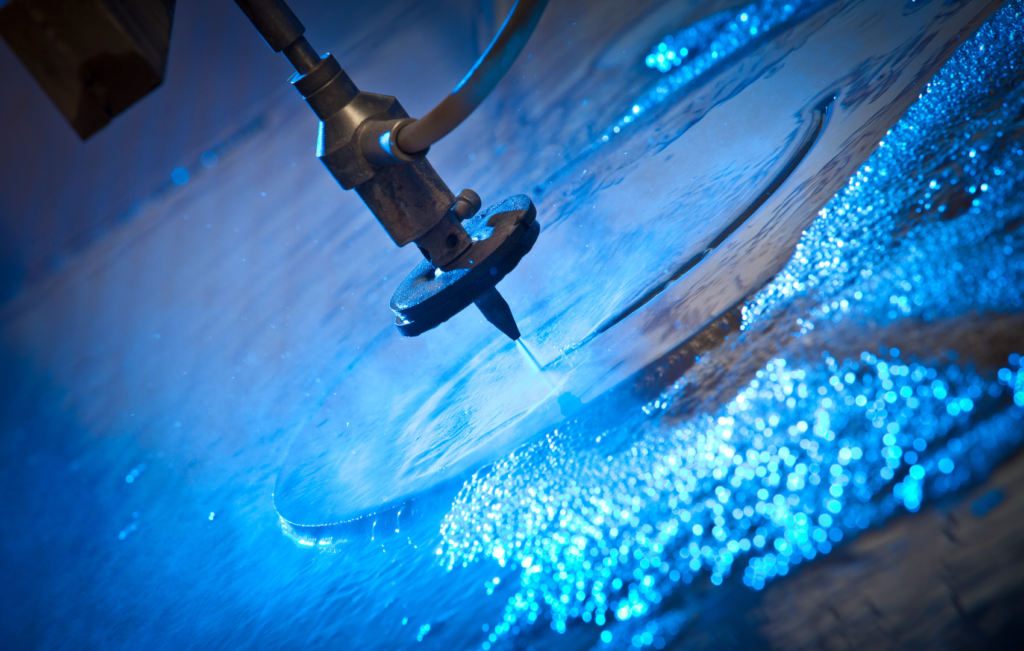

Waterjet cutting is an industrial process that uses waterjets that are emitted at high pressure to cut through various materials. Waterjet cutting is used even in the aerospace industry and vehicle workshops. Here, it is used to cut out different shapes and complex parts.

For complex materials, an abrasive is included in the waterjet cutting process to enhance the force used in cutting. Most materials can be cut with a waterjet cutting machine. Some of the materials that can be cut with a waterjet machine are such as; metals, glass, food, stone, composite materials, plastic, rubber, paper, and cardboard.

We will discuss how to go about cutting each and every one of these materials and the advantages of using the waterjet cutting method:

Metal

Waterjet machines are capable of cutting through all types of metals. These machines can cut through; titanium, copper, steel, brass, and aluminum among many other metals. Waterjet cutting machines use a process known as the cold-cutting process.

The cold-cutting process eliminates heat zones that are a result of chemical reactions and mechanical attributes contained within the product. It is recommended to cut metal parts that have been submerged in water so as to reduce any safety hazards within your working space.

Some materials such as dust particles, metal fragments, and filaments get caught in the water during the waterjet cutting process. Apart from the safety measure and benefits, waterjet is preferred for cutting through metal because it is efficient. This is due to the fact that the machine can cut through up to 300mm of steel.

This efficiency leaves room for metal fabricators to speed up the production line while having design flexibility. Projects are therefore done faster and better than with any other method. The end products also are clean-cut with smooth finishes.

The waterjet cutting process enables the metal fabricators to mill some features, bore holes into products, and smooth rough edges without having to do too much.

Stone

Waterjet cutting machines can cut through natural stones, as well as artificial ones. These machines can make designs out of stones such as; Porcelain, Granite, Marble, and Dekton. Waterjet cutting machines are fitted with mechanisms that outdo every other traditional stone-cutting technique.

Some of those traditional stone-cutting techniques like milling cutters, saws, and drills tend to be expensive and time-consuming. This is why waterjet cutting is the best technique for cutting through stone. This technique is automated, making it faster, more precise, and generally more efficient.

Unlike using a saw or a drill, waterjet cutting machines require no additional force to cut through stone especially if situated at a certain angle (usually a 45 degrees angle). In addition to that, man-made stones emit a lot of silica, whose exposure can be significantly reduced in the wet-cutting process that is implemented by waterjet cutting machines.

The computer-based software that is programmed into the waterjet cutting machines enables you to cut out complex and intricate designs such as tap holes. CAD is among the common software used today.

Glass

Glass cutting can be one of the most excruciating processes if you do not have the right tools to do it. It can also be time-consuming and expensive since it needs a tool change at almost every cutting stage not to mention glass is a delicate material.

Not to worry though, because cold water cutting processes can cut through glass with so much precision and caution while still producing the required design. As mentioned earlier, there are pre-programmed designs available for the carious waterjet cutting machines available. These designs enable clean-cut and high-quality glass products.

Composite Material

Fiberglass is an example of composite material. The distinguishing feature of such materials is that they are lightweight and delicate. This makes the cutting process difficult especially when using the improper cutting machine. Abrasive waterjet cutting is the most appropriate cutting method for materials such as these.

The waterjet cutting process ensures that there are no cracks or imperfections on the end product. It is precise and fast and it preserves the integrity of the fiberglass from the beginning of the cutting process to the very end.

Its technique is to channel a stream of the abrasive water jet that cuts through precisely. Other examples of composite materials that waterjet cutting can be used to cut through are such as; panel insulation, boat shell, and home insulations.